Out-of-stock products are a major challenge for any business. They lead to lost sales, frustrated customers, and damage to your brand’s reputation. Mastering the art of managing out-of-stock products is crucial for maintaining customer satisfaction and ensuring repeat business. This article will provide you with actionable strategies to not only handle out-of-stock situations effectively but also turn them into opportunities to build stronger customer relationships and ultimately increase sales. We will explore how to minimize the impact of out-of-stock products, communicate effectively with customers, and implement preventative measures to reduce future occurrences.

From proactive communication and offering suitable alternatives to implementing efficient inventory management practices, this guide covers essential techniques for mastering out-of-stock products. Discover how to transform a potentially negative customer experience into a positive one, fostering loyalty even when your desired product isn’t readily available. Learn how to keep your customers happy and coming back, even when facing the inevitable challenge of out-of-stock products. By understanding the strategies outlined here, you can turn a challenging situation into a competitive advantage.

Understanding the Impact of Out-of-Stock Items

Out-of-stock items can have a significant impact on a business, affecting both immediate sales and long-term customer relationships. Lost revenue is the most direct consequence. When a customer can’t find the product they want, they’ll likely abandon their purchase, leading to a missed opportunity for profit.

Beyond the immediate sale, stockouts can erode customer loyalty. A frustrating experience can push customers toward competitors, particularly in today’s competitive market. This can lead to a decline in market share and damage a brand’s reputation.

Furthermore, out-of-stock situations can also negatively impact operational efficiency. Employee time spent dealing with customer inquiries about unavailable products diverts resources from other important tasks. This can lead to decreased productivity and increased operational costs.

Strategies for Managing Out-of-Stock Products Effectively

Effectively managing out-of-stock products requires a multi-faceted approach. Prioritize transparency and proactive communication to maintain customer trust.

Substitute Products: Offering similar items can often satisfy customer needs and prevent lost sales. Highlight comparable products with similar features and benefits. Consider offering a small discount as an incentive.

Partial Fulfillment: If possible, ship available items immediately and backorder the remaining products. Clearly communicate expected shipping dates for backordered items.

Vendor Communication: Maintain close contact with suppliers to understand potential delays and secure accurate restocking information. Expedited shipping might be necessary in some cases.

Inventory Management: Regularly review inventory levels and implement demand forecasting techniques. This helps anticipate potential stockouts and adjust ordering accordingly. Consider safety stock levels for crucial items.

Communicating with Customers About Out-of-Stock Items

Transparency is key when dealing with out-of-stock products. Inform customers immediately if an item in their cart or that they are viewing is unavailable. Clearly state the out-of-stock status on the product page.

Offer alternative solutions. Suggest similar products that are currently in stock. This can help convert a potential lost sale into a successful one. Highlight the key features of the alternatives and how they compare to the original item.

Provide realistic expectations about restocking. If you have an estimated date, share it. However, avoid making promises you can’t keep. It’s better to under-promise and over-deliver in this situation.

Apologize for the inconvenience. A simple apology can go a long way in maintaining customer goodwill. Acknowledge the frustration an out-of-stock item can cause.

Make it easy for customers to contact you with further questions. Provide clear contact information, such as an email address or phone number. This allows customers to get personalized assistance regarding their specific needs.

Leveraging Back-in-Stock Notifications to Drive Sales

Back-in-stock notifications are a powerful tool for recapturing lost sales and fostering customer loyalty. By allowing customers to sign up for alerts when a desired product returns, businesses can effectively bridge the gap between disappointment and purchase.

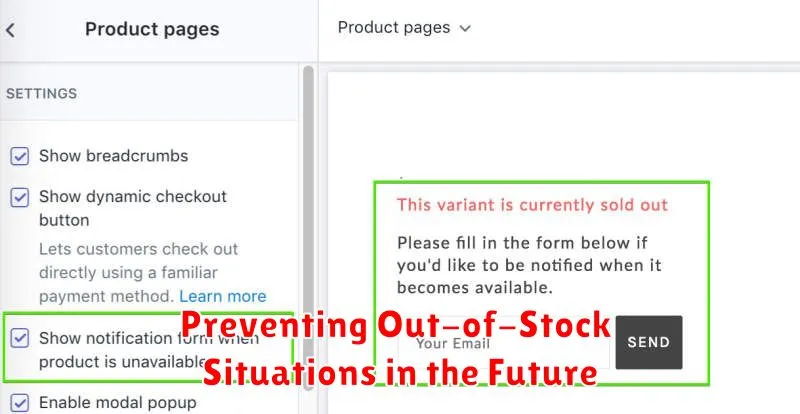

Implementing a streamlined notification system is key. Ensure the sign-up process is simple and requires minimal information from the customer. A clear call to action, such as “Notify Me When Available,” placed prominently on the product page, encourages engagement.

Delivering timely and accurate notifications is crucial. Automated emails or SMS messages should be sent immediately upon the product’s restock. This prompt communication demonstrates responsiveness and reinforces customer interest. Include a direct link to the product page for effortless purchasing.

Consider offering exclusive incentives to subscribers. A small discount or free shipping can further motivate customers to complete the purchase upon receiving a back-in-stock alert. This adds a layer of appreciation for their patience and strengthens their connection with your brand.

Preventing Out-of-Stock Situations in the Future

Proactive planning is key to minimizing future stockouts. Demand forecasting plays a crucial role. Analyze historical sales data, consider seasonality, and incorporate upcoming marketing campaigns to predict future demand accurately. This allows for informed purchasing decisions and optimized inventory levels.

Inventory management systems are essential for real-time visibility into stock levels. These systems provide alerts for low stock and can automate reordering processes. Implementing a robust inventory management system eliminates manual tracking and reduces the risk of human error.

Building strong relationships with suppliers is crucial. Open communication channels and established agreements on lead times ensure a consistent supply chain. Consider diversifying suppliers to mitigate the impact of potential disruptions from a single source.

Regularly review and refine your inventory control processes. Analyze past stockout situations to identify patterns and areas for improvement. This continuous improvement approach helps optimize stock levels and minimizes future disruptions.

Analyzing Out-of-Stock Data to Optimize Inventory Management

Effectively managing out-of-stock situations starts with a deep dive into your data. Analyzing out-of-stock data provides crucial insights for optimizing inventory and preventing future stockouts. This analysis should go beyond simply identifying which products are out of stock.

Key metrics to track include the frequency of stockouts for each product, the duration of each stockout, and the lost sales associated with each instance. This data helps pinpoint problematic products and reveals patterns in demand fluctuations.

Consider implementing a system to categorize out-of-stock occurrences. For example, are these stockouts due to supplier delays, inaccurate forecasting, or sudden surges in demand? Understanding the root cause allows for targeted interventions and more effective preventative measures.

By analyzing this data, you can make informed decisions about optimal reorder points, safety stock levels, and supplier relationships, ultimately leading to improved inventory management and reduced out-of-stock occurrences.

Turning Disappointed Customers into Loyal Ones

A customer facing an out-of-stock product is a delicate situation. Handled poorly, it can lead to lost sales and damaged reputation. However, with the right approach, this can be an opportunity to foster loyalty and even increase customer lifetime value.

Acknowledge the inconvenience. A simple, sincere apology goes a long way. Explain the situation briefly, whether it’s due to unexpected demand or supply chain issues. Transparency builds trust.

Offer a solution. Provide realistic alternatives. This could be a back-in-stock notification, a pre-order option, or suggesting a comparable product. If possible, offer a small incentive, such as a discount on their next purchase or free shipping.

Personalize the interaction. Train customer service representatives to empathize and empower them to offer tailored solutions. A personalized experience can transform a negative situation into a positive one.

Follow up. If a customer signs up for a back-in-stock notification, ensure they are promptly notified. This demonstrates reliability and reinforces their value as a customer.

Utilizing Alternative Product Suggestions

When a product is out of stock, offering alternative suggestions can significantly improve customer satisfaction and potentially save a sale. Strategic product recommendations prevent customers from leaving empty-handed and demonstrate proactive customer service.

Consider showcasing similar products with comparable features and benefits. For example, if a specific model of headphones is unavailable, suggest a different model from the same brand or a competitor’s product with similar specifications.

Upselling and cross-selling techniques are also valuable. If a customer is looking for a basic camera that is out of stock, suggest a slightly more advanced model (upselling). Alternatively, if a customer is purchasing a smartphone, suggest a compatible case or screen protector (cross-selling).

Ensure alternative suggestions are clearly presented and easily accessible on the product page. Using labels like “You Might Also Like” or “Customers Also Bought” can effectively guide customers towards relevant alternatives.